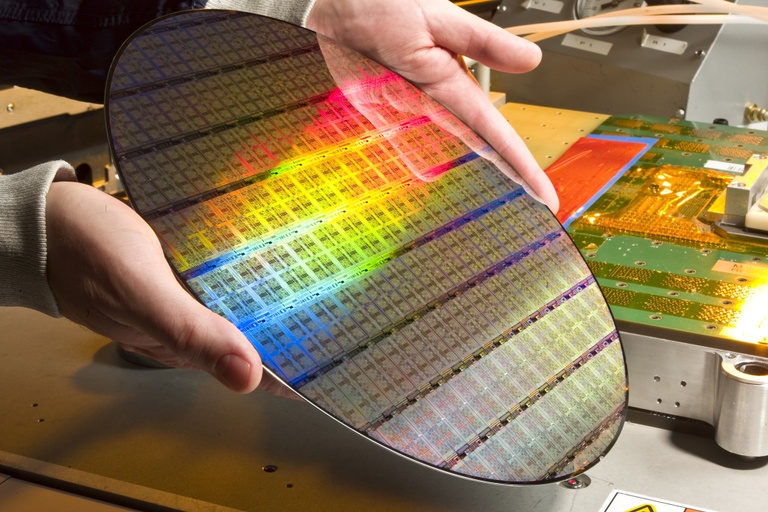

Fabricating microchips and semiconductor crystals in microgravity to benefit from the different physical behaviors, ultra-high vacuum, and other advantages. Microgravity-grown crystals have increased crystal size and suppressed impurities and defects.4

Updated: 2025-01-11

Created: 2018-12-07

Status

Since about 2023, this field is strongly re-emerging.

Terrestrial microfabrication techniques are difficult to transfer into microgravity. New methods have been and are being developed and some have been tested on a small-scale in space.

Microgravity Research Associates was founded in 1979 to produce gallium arsenide chips. Made in Space was selected by NASA in 2020 to develop autonomous semiconductor chip manufacturing.

In late 2024, Sierra Space signed memoranda of understanding with Astral Materials and Space Forge.

Applications

- Semiconductors

- Gallium Nitride (GaN)

- Gallium Nitride on diamond (GaN-on-diamond)

- Gallium Arsenide (GaAs)

- Silicon Carbide (SiC)

- Space-based microsensors

- Solar cells

- Radiation detectors

- Nanofabrication

Why & Solution

Semiconductor microchips are high value per mass products whose fabrication requires many of the resources available in low-Earth orbit. It is hypothesized that orbital fabrication of silicon microchip devices may be more economically attractive than traditional Earth-based fabrication based upon the inherent advantages of the space environment: vacuum, cleanliness, and microgravity.3

Gallium nitride, used to make LEDs, is difficult to solidify in large amounts at a time because its two constituent molecules don't always bind perfectly in order, leading to defects. Reducing the movement of the melted fluid as hotter and less-dense fluid rises, which occurs because of gravity, can decrease those defects — as can preventing the highly reactive substance from touching the sides of its container, according to Randy Giles, chief scientist at the Center for the Advancement of Science in Space. Someday, substances like that could benefit from in-space creation.2

Using orbital vacuum for enhanced semiconductor fabrication was pioneered in the Wake Shield project which produced ultra-high vacuums for epitaxial growth of high quality GaAs like materials. A proposed alternative uses the native Low Earth Orbit vacuum levels to achieve the silicon microfabrication processes needed for manufacturing silicon microchips. However standard terrestrial fabrication techniques are difficult to transfer into the microgravity and vacuum environment of space. They are optimized for using in-situ resources: water, power, air pressure and gravity that are plentiful on Earth. An alternative microfabrication process has been developed using the native vacuum environment which could replace wet terrestrial based microfabrication, with significant savings in equipment size, mass and consumables, while reducing cycle time.3

It is found that by developing new, dry processes that are vacuum compatible, fabricating semiconductor devices in orbit is both technically and economically feasible. The outcome is a synergistic, orbital-based methodology for micro-fabrication capable of building and delivering commercially marketable microfabricated structures. The base case modeled, production of 5,000 ASIC wafers per month, indicates that orbital fabrication is 103% more expensive than existing commercial facilities. However, optimization of process parameters and consumable requirements is shown to decrease the cost of orbital fabrication dramatically. Modeling indicates that the cost of orbital fabrication can be decreased to 58% that of an advanced, future Earth-based facility when trends of increasing process equipment costs and decreasing orbital transport costs are considered.3

Taking advantages of microgravity environment, amorphous semiconductors made a remarkable improvement both in quality and quantity. Space is considered to be a favorable environment for many things including the followings that were investigated: semiconductor joining by atomic adhesion, fabrication of thin films of diamond and amorphous silicon alloys, CVD processes, production of super-minute grains, light element analysis by SIMS (Secondary Ion Mass Spectrometry), and anti-proton generation by laser accelerators. This report reviews the potentials of material processing in space. Processing technologies of spacecraft construction materials, thin solid films, and fine alloys are reviewed. Light element analyzing method and antiproton storing technology for liquid metal MHD (Magnetohydrodynamic) power generator are also reviewed.5

Made in Space was selected to develop an autonomous, high throughput manufacturing capability for production of high quality, lower cost semiconductor chips at a rapid rate. Terrestrial semiconductor chip production suffers from the impacts of convection and sedimentation in the manufacturing process. Fabricating in microgravity is expected to reduce the number of gravity-induced defects, resulting in more usable chips per wafer. Market applications include semiconductor supply chains for telecommunications and energy industries.

Semiconductor Manufacturing in the Space Domain Workshop, 2023

- This workshop brought together a community of experts to explore the rich history of semiconductor and in-space manufacturing. These experts and their foundational research and collaboration are the driving force behind this paper. The workshop’s priority was to identify the 2030 goals that must be reached to make in-space semiconductor production a reality by 2050.

- The consensus was that the field needs to take the remaining years to de- risk investment from semiconductor corporations and private investors. To do that, the community needs to obtain more iterative data on promising semiconductor R&D in LEO. This would include the whole range of experiments in the semiconductor production phases such as crystal growth, wafer processing, epitaxial growth, circuit patterning, etc. Beyond synthesizing the takeaways from the workshop, the report describes the current state of semiconductor manufacturing in space and carves out a path for the future.

- Over the past three decades, the deteriorating discovery and growth of crystalline materials (DGCM) capacity in the United States has significantly stalled the domestic semiconductor industry. This report intends to regain U.S. attention to space-based semiconductor manufacturing and bring the field back from hibernation. The Vision for 2050 and Call to Action sections, informed by both industry and history experts, propose actionable solutions that can awaken the semiconductor industry from nearly 25 years of inactivity in space.

- The benefits of semiconductor manufacturing in LEO are clear. Earth’s gravitational forces pose substantial barriers to quick, high-yield semiconductor production. Beyond the scientific benefits of microgravity, there are substantial practical benefits to incorporating LEO-based manufacturing into the supply chain. Transitioning this industry into space is the only path forward if the US is to keep pace with the technological arms race unfolding across the globe.

- This report identifies opportunities to strengthen U.S. leadership in the LEO-based semiconductor manufacturing field. The industry urgently needs a roadmap for both immediate and long-term funding strategies that can support various components. Long- term government investments can help de-risk additional private investments, and funding student fellowship programs will drive workforce development.

- Beyond a need for funding, the industry needs a designated collaborative community ecosystem. This field is currently situated alongside several related fields, and gaining traction in established fields is certainly necessary. However, there is a clear need for a designated “home” and community that can draw on knowledge from academia, the space sector, and the semiconductor industry. A push towards this collaborative environment will only benefit the industry at large and give the United States a competitive edge in this growing field.

- This paper will explain the scientific basis for this industry in the proceeding sections. Discussions of the past and present of semiconductor manufacturing in LEO will provide the necessary context for the various author recommendations to develop the industry.

Companies

Astral Materials (Astral Forge) page at Factories in Space

- “Our technology utilizes microgravity as a manufacturing tool that can only be accessed in space,” Frick said in a statement about the partnership with Sierra Space. “This partnership with Sierra Space is a fantastic opportunity that allows us to focus on our strength: microgravity crystal growth.”

- Under the agreement, Astral Materials will work with Sierra Space on designing projects that could be flown on Sierra Space’s Dream Chaser vehicle. The agreement could also include cooperation on how to incorporate semiconductor manufacturing technologies into systems Sierra Space is developing for commercial space stations.

- Parabolic flights, which simulate microgravity for short periods, will allow Astral Materials to assess key furnace technologies before future demonstrations on the International Space Station or other commercial spacecraft.

- The company aims to use space's low gravity environment to address challenges in semiconductor crystal growth, a process critical to producing high-performance electronics.

- Astral Materials will test the furnace’s ability to confine molten metal in microgravity, evaluate its cooling system, and validate thermal models. The experiment will also assess hardware functionality, including an arc melting system, cameras, and sensors.

- While the primary goal of the flight is hardware validation, researchers will analyze silicon samples synthesized during the test to establish baseline performance metrics for future space-based production.

- The company does not anticipate significant improvements in crystal quality from the initial flight but expects the data to refine future experiments. Key metrics include furnace operability, repeatability, and the correlation between gravitational conditions and crystal formation.

- The furnace must be capable of heating silicon to at least 1,420 degrees Celsius for short durations in microgravity. It will also incorporate real-time monitoring through sensors and cameras, contain molten silicon at a fixed point, and produce spherical silicon samples.

- The project is scheduled to run through February 2026. Work will take place at Astral Materials’ facility in Mountain View, Calif.

SpaceWorks to Fly In-Orbit Manufacturing Tech in 2026-07-15.

- For Astral Materials, the mission’s baseline goal is to build flight heritage of its semiconductor crystal manufacturing technology, but Astral’s fingers are crossed that the reentry mission will result in real products it can sell.

- “We have customers who are interested…[But] since it will be our first time in orbit, we are not promising anything.” Dr. Jessica Frick, Astral’s cofounder and CEO, told Payload.

- Ultimately, Astral succeeds by building a reliable supply chain from space, Frick said, which depends first and foremost on having partners that can return their semiconductor crystals unharmed and on time.

ATLANT 3D Nanosystems page at Factories in Space

ESA BIC and ESA Idea (Denmark)

- Start Date - June 2023

- Budget - 130k EUR

- Building the 2nd generation of Nanofabricator 0g. The project focuses on various design and testing phases, including norms review, gas system design, and laboratory testing in simulated ISS environments.

- Work packages include Review of norms and requirements for mechanical, chemical and electrical parts; Gas system design; Mechanical design; Electrical design; Machine assembly and verification; Demonstration of printing multiple materials; Laboratory testing in simulated ISS environments and conditions; Identification of future steps towards implementation at ISS.

Blue Origin page at Factories in Space

ISRU

Since 2021, Blue Origin has been making solar cells and transmission wire from regolith simulants. We have pioneered the technology and demonstrated all the steps. Our approach, Blue Alchemist, can scale indefinitely, eliminating power as a constraint anywhere on the Moon.

- We start by making regolith simulants that are chemically and mineralogically equivalent to lunar regolith, accounting for representative lunar variability in grain size and bulk chemistry. This ensures our starting material is as realistic as possible, and not just a mixture of lunar-relevant oxides.

- We have developed and qualified an efficient, scalable, and contactless process for melting and moving molten regolith that is robust to natural variations in regolith properties on the Moon.

- For protection from the harsh lunar environment, solar cells need cover glass; without it, they would only last for days. Our technique uses only molten regolith electrolysis byproducts to make cover glass that enables lunar lifetimes exceeding a decade.

- Because our technology manufactures solar cells with zero carbon emissions, no water, and no toxic ingredients or other chemicals, it has exciting potential to directly benefit the Earth.

- Track 1 supports one-year trade studies to identify ISRU technology gaps and further define the benefits of including ISRU in mission architectures. In addition to Blue Origin, Track 1 participants include United Launch Alliance, the University of Illinois at Urbana and UTC Aerospace Systems.

- Track 2 supports component development and testing in simulated space environments. Companies selected for Track 2 are BlazeTech Corp., Paragon Space Development Corp., Skyhaven Systems and Teledyne Energy Systems.

- Track 3 focuses on extensive subsystem development and testing in simulated space environments. The Track 3 companies are Honeybee Robotics Spacecraft Mechanisms Corp. and OxEon Energy LLC.

- Blue Origin of Kent, Washington, $34.7 million.

- The company will advance an end-to-end in-situ resource utilization (ISRU) system that can extract oxygen, iron, silicon, and aluminum from lunar regolith simulant and use the extracted materials to produce solar cells and wire.

- Blue Alchemist to make solar cells on the Moon using moondust, 2023-07-27.

Faraday Technologies page at Factories in Space

LEO Manufacturing of 3D Printed Covetic Nanomaterials for Advanced Electronics, 2021 SBIR Phase I

This program will develop an in-space material manufacturing approach to leverage the unique capabilities of the International Space Station.

G-Space page at Factories in Space

G-Space aims at developing the ability to identify, define, and optimize the precise operational spectrum for space manufacturing to ensure manufactured products are at their highest quality and performance.

ATOM

NASA SBIR award in 2020 for Advanced Terrestrial to Orbital Manufacturing (ATOM) platform that builds on a terrestrial experimental technique, Gravity Elimination via Methods of Suspension (GEMS), enhanced through the addition of first-principles modeling, computational tools, and machine learning algorithms.

- G-Space is the only commercial company that provides a tool in advanced material manufacturing that harnesses the effect of gravity on material stability and narrows down the optimized 0G manufacturing envelope.

- The main objective of this SBIR Phase I is to develop a conceptual design of GEMS and to complete the buildout and beta testing of the ATOM platform, including a data manager, analysis and reporting system.

- The resulting platform will be validated using primarily in-house Heavy Metal Fluoride Glass data. In addition, the platform will be expanded to ingest selected material data from NASA’s Microgravity Database as well as an additional suite of high profit margin materials with potential for fabrication in a zero G environment.

ZBLAN IN-SPACE FIBER OPTICS MANUFACTURING

Raw Materials

A new product: ZBLAN (fluorozirconate) preforms for space manufacturing!

ZBLAN standard rods (⌀12.5mm, L=120mm) represent an exclusive new product, specifically designed for In-Space Manufacturing. Contact us for custom requirements.

Thermal Modeling For Fiber Drawing Automation

ATOM™ thermal modeling helps maintain optimal conditions for the fiber optics processing and manufacturing (including gravity correction)

In-Space Monitoring of Fiber Drawing Process

ATOM™ analytics and customized computer vision algorithms ensure that the optimal regime for microgravity processing is maintained. They also offer the ability to monitor and correct promptly key fiber optics parameters (fiber diameter uniformity, concentricity, etc.) during the in-space manufacturing process.

Quality Control and Validation (pre and post flight)

Provide best terrestrial manufacturing reference; inspection of a suite of fiber properties (attenuation, defects, etc.) and estimates of contributions (including gravity correction) that lead to loss of performance.

Intel page at Factories in Space

ODME EHD Inkjet process used to print nanocircuits of printed memory chips.

Maana Electric page at Factories in Space

With the support of European Space Agency - ESA, Maana Electric is prototyping a European system able to use material with low iron content and electricity to produce carbon neutral steel. This would enable to produce steel from low-grade material extracted near construction sites, reducing supply chain costs, addressing the rapid depletion of high-grade iron and promoting Europe as a world leader in green technology.

TerraBox

Maana Electric’s TerraBox is a fully automated factory capable of producing solar panels using only sand and electricity as inputs. The TerraBox fits within shipping containers, allowing the TerraBoxes to be transported to deserts across the globe and produce clean renewable energy.

Reactor for production of heat and pure ISRU metal during lunar nights through thermite reaction

Thermite reactions are chemical reactions between a pure metal and a metal oxide, which release a lot of energy and form a more stable metal oxide and a reduced metal. These reactions can refine many different metals with a relatively high purity, and the resulting metals could be used to build on the Moon. This early technology development project aims to develop a thermite reactor with the double role of producing the metals needed for building and living on the Moon, and generating heat to keep astronauts warm at night.

In 2024, announced the successful development of our first fully ISRU solar panel. Crafted with 99% low-value feedstock. 99.8% of its materials were made from lunar resources.

Microgravity Research Associates page at Factories in Space

Formed in 1979 for the purpose of engaging in materials processing in space. Plans to grow crystals in space, starting with gallium arsenide.

Redwire (Made in Space) page at Factories in Space

Orbital Microfabrication

Working on manufacturing electronics and semiconductors in LEO. Experiment is scheduled to fly to ISS on CRS-28 in 2023.

Developing an autonomous, high throughput manufacturing capability for production of high quality, lower cost semiconductor chips at a rapid rate. Terrestrial semiconductor chip production suffers from the impacts of convection and sedimentation in the manufacturing process. Fabricating in microgravity is expected to reduce the number of gravity-induced defects, resulting in more usable chips per wafer. Market applications include semiconductor supply chains for telecommunications and energy industries.

Manufacturing of Semiconductors and Thin-Film Integrated Coatings (MSTIC)

- More than a dozen payloads representing diverse research areas will launch to the International Space Station (ISS) onboard Northrop Grumman’s 20th Commercial Resupply Services mission contracted by NASA. The launch is planned for no earlier than January 29, 2024.

- This project examines the effects of microgravity on deposited thin films used in semiconductor manufacturing. Manufacturing these films in microgravity may improve their quality and reduce the materials, equipment, and labor required. The investigation also explores differences in the microstructure of thin films produced in microgravity and on the ground.

- “We are strategically expanding our space manufacturing capabilities to reach new markets and drive innovation that could support U.S. leadership in the global semiconductor ecosystem. This pathfinder mission represents an exciting step to validate space-based manufacturing processes that could deliver superior components beyond what is capable on Earth, which could have real impact on semiconductor supply chains,” said John Vellinger, President of Redwire’s In-Space Industries.

- The MSTIC payload was developed in partnership with the ISS National Laboratory and through NASA’s In Space Production Applications Flight Demonstrations program, which is focused on ensuring U.S. leadership of in-space manufacturing to demonstrate the production of advanced materials and products for terrestrial markets.

- MSTIC is the latest addition to Redwire’s robust portfolio of space biotech and in-space manufacturing capabilities, which spans over 20 facilities developed for the ISS, with eight currently operating on orbit. The company plans to open a 30,000 square foot microgravity payload development facility and mission operations center in Floyd County, Indiana, to support increased production of critical technologies for human spaceflight missions and commercial microgravity research and development in LEO.

Space Forge page at Factories in Space

"We’re still aiming for a first launch at the end of 2022 but that really depends on what rockets are available," said Andrew.

- "But we will be in orbit within 18 months certainly. "Some parts have arrived already and we’re setting up the clean room, which is almost ready for us to start assembling things – we can produce three ForgeStar Ones at a time in there.

- "By 2025 we want to be doing 12 missions to a year and by the end of the decade they'll probably be weekly. With that said we've probably already met our capacity here so we're in discussions with the Welsh Government about finding a new space for us."

Reuters: World’s first reusable satellite to offer in-space manufacturing.

Semiconductors

"Each mission is capable of producing more than a million [semi-conductor] chips per flight."

Microgravity as a service

Aether

- The next-generation prediction system.

- Precisely engineered tracking, capture and recovery.

- Designed for convenience, cost and customer satisfaction.

- Speedy return of your payload post mission"

ForgeStar-0

- The spacecraft will test the company’s proprietary re-entry shield, which during future operational missions would protect a satellite traveling through the searing heat of the atmosphere, targeting a landing ellipse of just hundreds of meters.

- While the exact technology is under wraps, Western says each shield has an “umbrella-like” deployment, unfurling upside down ahead of the spacecraft to start. Then, once through the thick atmosphere, the shield doubles as a parachute, slowing the spacecraft for a gentle touchdown.

- ForgeStar-0 will be purposefully oriented to burn up in the atmosphere, providing useful data points about how the shield copes with re-entry. But a true test will come possibly as early as next year, when the company launches its ForgeStar-1 satellite to demonstrate in-space production of semiconductors, which have a 10-to -100-time performance improvement over semiconductors made on Earth.

ForgeStar-1

- The microwave-sized ForgeStar-1 satellite contains a miniature, automated chemistry lab that will allow the team to remotely mix various chemical compounds and develop new semiconducting alloys once the satellite is in orbit.

- But rather than sending the materials back to the planet, ForgeStar-1 will beam the results of these experiments to scientists digitally as this satellite is not designed to return to Earth.

- Space Forge has confirmed the successful launch and in-orbit communication with ForgeStar®-1, the UK’s first in-space manufacturing satellite, developed entirely in Wales.

- ForgeStar-1 launched aboard the Transporter-14 rideshare mission from SpaceX’s facilities at Vandenberg Space Force Base in California.

- This first-of-its-kind in-orbit manufacturing demonstration is designed to prove the viability of producing advanced materials in the unique environment of space.

ForgeStar-2

US Office

The Cardiff, Wales-based startup focused on fabricating high-value materials in space is looking for a U.S. location for manufacturing ForgeStar satellites and payloads for U.S. customers.

- “We’ve had a lot of taps on the shoulder from both government and commercial players that are interested in our core capabilities,” Space Forge CEO Joshua Western told SpaceNews.

- Space Forge intends to manufacture semiconductors, alloys and biological materials in orbit.

- An upgraded version, ForgeStar-1A, is scheduled to launch later this year on a SpaceX Falcon 9 rideshare flight. ForgeStar-1A will demonstrate Space Forge’s in-space manufacturing capability and gather safety data, Western said.

ForgeStar System

- As opposed to ablative heat shields, like those used on SpaceX’s Dragon capsule, which require replacement after each mission, Space Forge says it built its “Pridwen” heat shield to be large enough to radiate away the heat generated by atmospheric reentry. The shield, made out of a high-temperature alloy, was designed to fold inside the launcher for lift-off and unfold when the spacecraft makes its return to Earth.

- Moving away from ablative heat shields is one way Space Forge hopes to set itself apart from its competitors.

- The company has also developed an uncrewed water vehicle, “Fielder,” which will maneuver itself under ForgeStar and “catch” it in a soft landing. The idea is to reduce stress on sensitive payloads inside the vehicle as much as possible, while also reducing the need for spacecraft refurbishment.

- “The space station is a great laboratory, but it’s not a factory,” Bacon said. Nor is in-space manufacturing as simple as turning a Dragon capsule, the most-used cargo and crew vehicle in history, into an orbital factory. The capsule simply isn’t optimized for it — on cost or engineering, he explained.

- In addition to cost, the mechanics of Dragon’s reentry could pose problems for some materials, like live biological cultures. “We’ve spoken to biological customers who’ve lost their three-year in-development experiments in the last millisecond of landing,” due to the high-shock of landing, Bacon explained.

PECVD Tool Design

PECVD Tool Design: Results: Adaptations to tool required for semiconductor manufacturing. How are the key process parameters changed in LEO?

- Access to regular cadence of launch and return from orbit.

- As platform agnostic as possible.

- Easily adaptable to other CVD processes.

- Dimensions: 3U

- Mass: 4.5 kg

- Power Consumption: < 3W

Tool capable of firing up a plasma a fraction of the conventional power requirements of terrestrial tools.

News

Space Forge Secures £22.6M for In-Space Manufacturing Platform, 2025-05-14.

- Welsh in-space manufacturing company Space Forge has raised £22.6 million in a Series A funding round led by the NATO Innovation Fund.

- Space Forge explained in its 14 May update that the funding will be used to develop its upgraded ForgeStar-2 platform and to support its upcoming first in-orbit demonstration mission.

United Semiconductors page at Factories in Space

AFRL sponsorship recipient wins NASA space manufacturing contract, 2022-05-26.

- Air Force Research Laboratory research sponsorship recipient, United Semiconductors, LLC (USLLC), is one of eight companies selected to work on a three-year, $21 million NASA contract to manufacture tools in space.

- The key technological innovation of this work is to grow large diameter semiconductor crystals with high optical quality, which have use in several U.S. Air Force and U.S. Space Force systems of interest.

- Based on the unique properties their material demonstrated, NASA awarded United Semiconductors a contract to develop new technologies using the benefits of microgravity for in-space manufacturing of advanced materials. USLLC will grow semiconductor crystals used in electromagnetic sensors. Under microgravity conditions, the company hopes to produce larger crystals with significantly fewer defects. If successful, the crystals grown in space would produce usable wafers or thin slices of semiconductors used to build circuits.

- “The ternary semiconductor crystals that [AFRL] funded him to develop are incredibly challenging,” Schunemann said. “Numerous obstacles had to be overcome to achieve device-quality crystals, including severe segregation, compositional nonuniformity, constitutional supercooling, inclusions, voids, cracks and grain boundaries. The fact that he has been able to achieve reproducible crystals with high optical quality, uniformity and precise composition control, and scale these crystals to very large diameters, is nothing short of astounding!”

- Compared to State-of-the-art industrial furnaces operated under similar conditions and operating temperature, USLLC Space Furnaces are designed to consume 3-4x less power with 25% volume reduction and 20% weight reduction.

- Space crystal growth ampoule designs are significantly different than terrestrial crystal growth ampoules.

- The designs must account for Marangoni convections, absence of buoyancy and convection, vibration, and mechanical safety (for flight launches), ease for astronauts to handle and operate, precision designs to enable crystal growth using the thermal profiles in the space furnaces, leverage the micro-gravity conditions

- Leveraging Microgravity for Container Designs

- Weightlessness: Ultra-large Diameter Crystals

- Container-less Crystal Growth

- Marangoni Convection: Enhanced Mixing

- G-Jitters: Periodic Deposition

- Buoyancy: Spatial Alloy Dispersion

- Absence of Natural Convection: Controlled Diffusion

- Orientation of residual gravity: Nutrient Feeding

- Raw Material Form Factor for Space Crystal Growth: Tailored Nucleation.

- New crystal growth & wafer processing approaches and device designs needs to be developed for leveraging the full potential of In-Space manufacturing.

United Semiconductors Crystal Growth Payload Arrives at the ISS Onboard SpX-31, 2024-11-04.

- The first of its kind semiconductor crystal manufacturing experimental payload headed to the International Space Station (ISS) launched on the SpaceX-31 resupply mission

- In-Space manufacturing leveraging microgravity conditions has numerous technological potentials based on scientific research conducted over the past 5 decades. However, there remains many technical gaps for translating scientific success into large scale manufacturing efforts.

- Through a NASA funded In-Space Production Applications (InSPA) grant, supplemented by a National Science Foundation (NSF) SBIR funding, USLLC is addressing key challenges and feasibility of microgravity manufacturing. This will pave the path for long term development of critical tools and processes for high throughput production of semiconductor-based materials leveraging the beneficial effects of microgravity.

- The company plans to deploy crystals manufactured in space for potential use in next generation semiconductor technologies, including autonomous systems, sensing, artificial intelligence, aerospace, and defense components. The use of microgravity is expected to boost performance, yield and reliability of devices fabricated with space manufactured materials.

- USLLC’s SpX-31 payload is for production of a novel class of Semimetal-Semiconductor Composite Bulk Crystals. The investigation will be conducted in the NASA-owned Solidification Using a Baffle in Sealed Ampoules (SUBSA) furnace.

- Partners on this investigation include payload implementation partners, Redwire Space Technologies, Inc. and CSS, Inc., Axiom Space and third-party validation partner, AFRL’s Wright Patterson Air Force Base (WPAFB). The learnings generated from this project will lay the groundwork for the development of an in-space manufacturing platform for semiconductors.

- “This mission is focused on microgravity enabled semiconductor manufacturing and will leapfrog prior science investigations in the SUBSA furnace to a commercial scale process development on ISS”. USLLC is leveraging its two decades of proven track-record in terrestrial III-V compound semiconductor alloy bulk crystal production and component designs for its microgravity materials development.

Earthly Solution Risk

Exists, because lots of research is happening to keep up with the Moore's law and economies-of-scale likely favor Earth in the near-term.