High quality optical fibers with much lower attenuation and much wider wavelength range (spectrum window).

Updated: 2025-01-11

Created: 2018-11-01

Applications

- Telecommunications.

- Lasers for medical & scientific applications (photonics).

- Military applications like night vision and infrared countermeasures.

- Remote sensing payloads.

- Thermal imaging.

- Spectroscopy (imaging).

- Radiation resistant data links.

- Glass alloys.

Why & Solution

Making ZBLAN glass results in crystallization or the formation of tiny imperfections. Research has shown that it does not happen in microgravity.

Telecommunications sector is facing exponential growth in bandwidth transmission. With almost half of the population in the world not yet online and much higher bandwidth applications like 5G networks, 4K streaming and virtual reality applications still to come, the growth will not be slowing down any time soon. Current solution is to keep building new undersea cables.

Major advantages of ZBLAN are much lower attenuation (signal weakening) and much wider wavelength range. Lower attenuation would reduce the need for repeaters, which are also a security risk and increase latency. Wider wavelength range would allow the transfer of much more data through ZBLAN cable by using many lasers with different wavelengths. There is a large number of spacecraft, scientific, medical and defense equipment working in the infrared wavelength range.

- Apsidal of Los Angeles is developing a Universal Glass Optics Manufacturing Module capable of processing various types of complex glass in space from which fibers, magnetic fibers, super-continuum sources, capillary optics and adiabatic tapers can be drawn. One of their key innovations is a custom Laser Doppler Sensor for real-time in-situ analysis and feedback control of the manufacturing process. Additionally, this technology is Artificial Intelligence (AI) assisted to be adaptive to optimize production in a low-Earth orbit environment. The microgravity environment of space is needed because convection and sedimentation in development on Earth causes separation of complex glass elements creating crystallization, thus creating defects which reduce performance. Market areas for products from this module include specialty fibers for communications, medical diagnostics, remote sensing, X-ray optics, and laser processing.

- DSTAR Communications of Woodland Hills, California, has established a team to create an external material processing platform on the International Space Station with autonomous, high throughput manufacturing capability. Markets for products manufactured by this facility include infrared optical fibers in medical and defense applications and ultralight solar arrays for commercial and military space platforms. The unique microgravity environment of space eliminates convection and sedimentation that occur on Earth, enabling the manufacture of premium quality materials and products with fewer defects and improved performance. In addition, the vacuum of space enables vacuum deposition in the same facility for improved reliability and improved functionality of the resulting products. The DSTAR Communications team includes partners FOMS of San Diego, California, Visioneering Space of Boise, Idaho, and Lunar Resources of Houston.

- Made In Space will be developing a Glass Alloy Manufacturing Machine (GAMMA), an experimental system designed to investigate how glass alloys form without the effects of gravity-induced flaws. The microgravity environment of space is expected to enable much higher quality glass products by eliminating the Earth-based impacts of convection, sedimentation, and solute buildup, which lead to nucleation, or crystal-forming sites in the materials. This system could improve processes for commercial product development. Product applications include optical fiber, lenses, and optical devices across several market segments including telecommunications, sensors and laser technology industries.

Jeff Foust wrote in September 2022 that experiments in ZBLAN fiber production have yet to convert into commercial production and producing such fibers in space was turning out to be harder than expected. Apsidal’s De says a breakthrough is still possible with ZBLAN fiber, given enough effort. “Your successes sometimes come very suddenly,” he said. “You can see very large improvements come very quickly.”

Companies

ACME Advanced Materials page at Factories in Space

Their social media platforms have been quiet for 2 years. The primary founder Rich Glover, who is still listed as the contact on website, has marked on LinkedIn that he stopped working there in 2018.

Apsidal page at Factories in Space

- UNIGLO was a science and technology demonstrator whose ISS mission had four primary scientific objectives: mapping thermal profiles in microgravity, measuring phase transitions in extic glasses, drawing ZBLAN fibers under microgravity conditions, and employing a novel custom laser-interferometer and an AI-feedback control system to improve spooled fiber quality in-situ.

- For this talk we will discuss glass- and crystallization-transition test results from the International Space Station (ISS) which essentially pave the way for advancing the production of high-valued exotic-glass optical fibers in low-Earth orbit. The comparative behavior of ZBLAN glass undergoing phase transitions in both microgravity and Earth’s gravitational environments was investigated and we find the bulk-glass to be more resistant to crystallization in space. However, the surface continues to be vulnerable under ambient conditions.

- We conducted a set of 10 differential-calorimetry tests in the Microgravity Science Glovebox, including 2 sets of controls. A similar number of control tests were performed on earth. We subjected our samples to very high temperatures exceeding 430 C and studied and identified various types of crystal formation. We identified several crystals that do manage to form in space that can be orders of magnitude larger and very well faceted.

- However the fluoride glass also seems to harden in microgravity and becomes more resistant to crystal growth in the bulk. This manner of data collection and metrology is vital to inform future mitigation strategies for manufacturing advanced exotic-glass optical fibers in space.

DSTAR Communications page at Factories in Space

The DSTAR Communications team includes partners FOMS of San Diego, California, Visioneering Space of Boise, Idaho, and Lunar Resources of Houston.

Space Enhanced Crystals (SPECS)

Halide Optical Fibers

Advanced Halide Optical Fibers for In-Space Manufacturing, 2024.

Flawless Photonics page at Factories in Space

Flawless Photonics, Inc. of Los Altos Hills, California, in partnership with the University of Adelaide, Axiom Space, and Visioneering Space has been selected for their proposal to develop specialized glass manufacturing hardware to process Heavy-Metal Fluoride Glasses (HMFG) in microgravity.

- HMFG glasses are used in the terrestrial manufacturing of exotic optical fibers and other optics applications. Without convective forces present in 1g, HMFG made in microgravity are expected to achieve the ideal amorphous microstructure during synthesis, eliminating light scattering defects that limit lasing power and transmission over long fiber lengths.

- Flawless Photonics, another 2022 InSPA award recipient, plans to develop specialized glass manufacturing hardware to process Heavy-Metal Fluoride Glasses in microgravity for terrestrial manufacturing of optical fibers and other optics applications.

They say to be pioneering the first profitable supply chain in space starting with the world’s most perfect optical fibers that will outperform silica fibers by more than 10x for industries including lasers, sensors, medical devices, and data communications. Later they are planning to produce an exciting array of superior photonic glass products to meet the emerging demands of many industries and applications.

Advancing SpaceFiber Manufacturing in Microgravity Onboard the ISS

- More than a dozen payloads representing diverse research areas will launch to the International Space Station (ISS) onboard Northrop Grumman’s 20th Commercial Resupply Services mission contracted by NASA. The launch is planned for no earlier than January 29, 2024.

- This investigation will leverage the space station to test microgravity-based glass drawing processes on a Flawless Photonics ZBLAN manufacturing platform. The project’s goal is to demonstrate the theorized benefits of manufacturing ZBLAN fibers in microgravity to effectively eliminate gravity-induced defects. By harnessing the unique environment of microgravity, Flawless Photonics aims to produce fibers that offer significantly enhanced performance for a wide range of applications, including advanced laser systems and telecommunications devices for both space and Earth applications.

- IP: Visioneering Space Corporation

Flawless Photonics Kicking Glass, SpaceNews, 2024-02-23

- Silicon Valley startup Flawless Photonics has produced more than 5 kilometers of ZBLAN on the International Space Station in two weeks.

- It’s an achievement that alluded other companies that tried to produce the fluoride glass in microgravity.

- Flawless Photonics’ “unprecedented results” are likely to prompt investigations into new types of glass that could be “very important for our defense industry and our national security,” said Rose Hernandez, director of InSpace Production Applications for the ISS National Lab. “Now they can tap into technologies that were not possible on Earth.”

- “The moon shot here is making undersea cables with ZBLAN,” said Michael Vestel, Flawless Photonics chief technology officer and vice president.

- So, instead of having inline optical repeaters to boost the signal in submarine communications cables “every 40 or 50 kilometers, you could have them at distances of 10 or 100 times that,” said Vestel, who earned a PhD in materials science and engineering from the University of California, Berkeley. “Why does that matter? It turns out the power of those amplifiers consumes energy on the order of 1 percent to 1.5 percent of the entire global budget of energy.”

- Samples of ZBLAN produced by Flawless Photonics are scheduled to return to Earth on a SpaceX’s Commercial Resupply Services flight in April. At that time, NASA and an independent third party will study the quality and composition of the optical fibers produced on ISS.

- The European Space Agency and Luxembourg Space Agency provided funding for Flawless Photonics’ machine for drawing optical fiber in space. The ISS National Laboratory paid for ISS transportation and installation in the Microgravity Science Glovebox.

- ZBLAN is produced from a heated cylindrical preform with a glass core surrounded by cladding and coating. As the fiber is pulled, it thins out and eventually breaks. A key feature of Flawless Photonics’ microgravity machine is its ability to restart the process of pulling optical fiber after the fiber breaks.

- For Flawless Photonics, the next step is making preforms in space. NASA’s In Space Production Applications program is paying for a preform manufacturing experiment by Flawless Photonics, Australia’s University of Adelaide, Axiom Space and Visioneering Space.

Commercial-grade optical fibres fabrication in space, 2024-03-28.

- University of Adelaide-produced special glass rods have been transformed into over eight km of optical fibre aboard the International Space Station.

- Professor Heike Ebendorff-Heidepriem, an Australian Research Council Industry Laureate Fellow and deputy director of IPAS, along with her ANFF-Optofab team, supplied 20 ZBLAN glass rods for ultra-low loss optical fibre.

- Upon the return of these space-drawn fibres to Earth, Flawless Photonics and the team at IPAS will conduct various analyses and experiments to determine the properties of the space-drawn fibres relative to fibres drawn on Earth.

- A technology development project from Flawless Photonics sought to validate the company’s technology for manufacturing high-value, optical-quality glass materials, like ZBLAN, in microgravity. ZBLAN can perform up to 100 times better than the silica fibers commonly used to connect our digital world today, but gravity-induced defects in fibers produced on Earth limit its full potential.

- This project seeks to demonstrate that production in microgravity can reduce these defects, resulting in higher-quality fibers than can be produced terrestrially. Preliminary results demonstrated significant improvements in the quantity of optical fiber produced in space.

- From mid-February to mid-March, the company manufactured a total of more than seven miles (11.9 km) of optical fiber on station. The kilometers of glass fiber drawn in space will now undergo independent analyses to determine if they have superior performance characteristics.

FOMS (Fiber Optic Manufacturing in Space) page at Factories in Space

FOMS (Fiber Optics Manufacturing in Space) is focused on optical fiber manufacturing in microgravity.

Fiber Optic Manufacturing in Space (FOMS) Inc. presented the results Nov. 7 of its successful campaign to produce optical fiber on the International Space Station.

Our equipment offers the following set of capabilities for fiber production in space:

- Production capacity up to 50km per mission in a small and cost-effective form factor.

- Multiple doped and undoped fibers fabrication option in a single payload.

- Processing temperature range exceeding 1000°C that covers most of known glasses.

- Gravity immune manufacturing hardware for best fiber in any orientation or gravity.

- Intuitive software interface with option of automatic optimization of the fiber quality.

- The innovations will be used to demonstrate automated production of high-quality optical fibers in microgravity for use in applications on Earth. The payloads are Space Fibers 3 developed by San Diego-based FOMS, Inc. and the Orbital Fiber Optic Production Module (ORFOM) from Mercury Systems of Torrance, California.

- Fiber manufacturing runs using the new hardware from FOMS and Mercury Systems are expected to last up to two weeks for each payload on the station. NASA’s InSPA program will assess results to help inform future hardware improvements and steps toward potential optical fiber manufacturing in space in the coming years.

G-Space page at Factories in Space

G-Space aims at developing the ability to identify, define, and optimize the precise operational spectrum for space manufacturing to ensure manufactured products are at their highest quality and performance.

ATOM

NASA SBIR award in 2020 for Advanced Terrestrial to Orbital Manufacturing (ATOM) platform that builds on a terrestrial experimental technique, Gravity Elimination via Methods of Suspension (GEMS), enhanced through the addition of first-principles modeling, computational tools, and machine learning algorithms.

- G-Space is the only commercial company that provides a tool in advanced material manufacturing that harnesses the effect of gravity on material stability and narrows down the optimized 0G manufacturing envelope.

- The main objective of this SBIR Phase I is to develop a conceptual design of GEMS and to complete the buildout and beta testing of the ATOM platform, including a data manager, analysis and reporting system.

- The resulting platform will be validated using primarily in-house Heavy Metal Fluoride Glass data. In addition, the platform will be expanded to ingest selected material data from NASA’s Microgravity Database as well as an additional suite of high profit margin materials with potential for fabrication in a zero G environment.

ZBLAN IN-SPACE FIBER OPTICS MANUFACTURING

Raw Materials

A new product: ZBLAN (fluorozirconate) preforms for space manufacturing!

ZBLAN standard rods (⌀12.5mm, L=120mm) represent an exclusive new product, specifically designed for In-Space Manufacturing. Contact us for custom requirements.

Thermal Modeling For Fiber Drawing Automation

ATOM™ thermal modeling helps maintain optimal conditions for the fiber optics processing and manufacturing (including gravity correction)

In-Space Monitoring of Fiber Drawing Process

ATOM™ analytics and customized computer vision algorithms ensure that the optimal regime for microgravity processing is maintained. They also offer the ability to monitor and correct promptly key fiber optics parameters (fiber diameter uniformity, concentricity, etc.) during the in-space manufacturing process.

Quality Control and Validation (pre and post flight)

Provide best terrestrial manufacturing reference; inspection of a suite of fiber properties (attenuation, defects, etc.) and estimates of contributions (including gravity correction) that lead to loss of performance.

Mercury Systems (Physical Optics Corporation, POC) page at Factories in Space

- Physical Optics Corporation (POC) proposes to develop the Orbital Fiber Optic Production Module (ORFOM), which addresses NASA's needs for sustainable space operations and full utilization of the International Space Station (ISS).

- ORFOM is an orbital scientific payload that will be capable of optical fiber draw in zero gravity onboard the ISS, and specifically "ZBLAN" fluoride glass fiber which is capable of transmission from ultraviolet (UV) to mid-wave infrared (MWIR).

- When produced on Earth, ZBLAN glass fibers exhibit excessive loss due to crystallization; however, this crystallization can be suppressed in zero gravity. Low down-mass and the high value of low-loss ZBLAN fiber make it an ideal candidate for commercial ISS utilization. During Phase I, we will design and assemble a prototype fiber draw system that will have the size, weight, and power (SWaP) to fit into a NanoRacks ISS payload bay.

- We will also demonstrate a novel fiber draw process using an in-situ coating and a method to start the fiber draw from a preform that can be used in zero gravity.

- In Phase I, POC will develop a compact Technology Readiness Level (TRL)-4 version of the ORFOM, and formulate a preliminary Mission Plan, which will be implemented in Phase II. We will also explore commercial applications such as rare-earth-doped fiber for fiber lasers.

- The innovations will be used to demonstrate automated production of high-quality optical fibers in microgravity for use in applications on Earth. The payloads are Space Fibers 3 developed by San Diego-based FOMS, Inc. and the Orbital Fiber Optic Production Module (ORFOM) from Mercury Systems of Torrance, California.

- Fiber manufacturing runs using the new hardware from FOMS and Mercury Systems are expected to last up to two weeks for each payload on the station. NASA’s InSPA program will assess results to help inform future hardware improvements and steps toward potential optical fiber manufacturing in space in the coming years.

Redwire (Made in Space) page at Factories in Space

ZBLAN

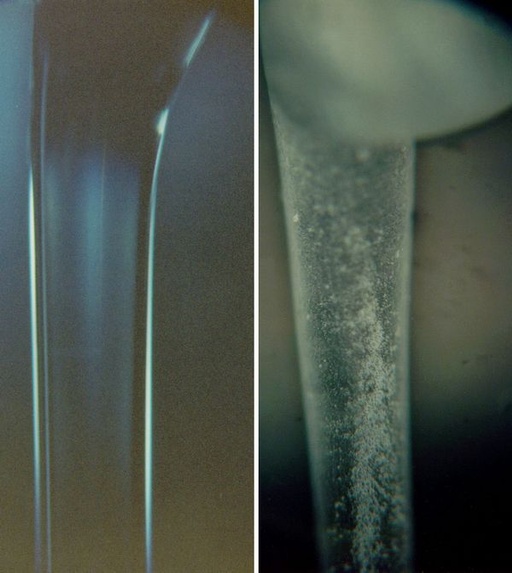

In parallel they privately funded the development of expertise and technology to produce fibre in space. Their first fibre machine visible on Figure 5 was launched to the ISS in 2017 to test the system and draw some fiber.

Varda Space Industries page at Factories in Space

Space factories for Earth-bound products. Varda Space Industries is building the world's first commercial zero-gravity industrial park at scale. In the near-term, Varda is laser-focused on manufacturing things off Earth that are highly valued on Earth. Over the long-term, Varda can build the infrastructure needed to enable humanity to industrialize space.

Economical Reentry Capsules for Hypersonic Testing, 2021 SBIR Phase II

Advanced strike, surveillance, interceptor, orbital transfer, and orbital reentry vehicles need to travel at hypersonic speeds for at least a portion of their trajectory. This hypersonic flight regime can generate flow energies in excess of 24MJ/kg, molecular excitation, and chemical dissociation. In turn, these thermo-chemical processes affect vehicle aerodynamic coefficients, heat transfer rates, and effectiveness of onboard sensors. Despite its importance, this flight regime remains poorly understood due to the difficulty in generating flight-accurate hypersonic flows in the lab or ground test facilities. Modern ground test facilities cannot simultaneously match all the hypersonic flow parameters leading to a compromise on test conditions (Reynolds number, free stream chemistry, test time, etc). Likewise, modern state-of-the-art hypersonic fluid dynamics codes are not fully validated because flight-relevant validation data does not exist. The resultant uncertainties associated with hypersonic flows lead to vehicle failures, increase development costs, and lengthen development timelines. The best way to study hypersonic flows and test hypersonic materials is to fly at hypersonic speeds. Unfortunately, modern dedicated hypersonic flight test programs can cost over $100 M per flight and adapting additional sensors to qualified or crewed reentry vehicles for flight testing introduces unacceptable risks. Alternatively, Varda is designing a reentry vehicle for its commercial business that can be leveraged for readily available and cost-effective hypersonic environment and material testing.

Varda Space Industries is an in-space manufacturing company that is building on-orbit factories to manufacture ZBLAN fibers and reentry capsules to return ZBLAN to Earth. The first test flight is expected in 2023. Varda is optimizing these capsules for cost and repeatability to support Varda’s primary business of selling products produced in orbit. These optimization targets also make Varda’s capsules an ideal candidate for the Air Force’s hypersonic validation and test efforts.

Revenue Estimation

One kilogram of ZBLAN yields 2.2 kilometers of ZBLAN fiber.1

Another source claimed that in theory a kilogram of preform can produce 3 km of fiber, but thickness not specified. 3

Articles by NASA state that one kilogram of exotic glass feedstock can be expected to produce from 3 to 7 kilometers of fibers in under an hour in microgravity. 3

Selling 2 km of fiber at $150 per meter would total to $300,000. Best case scenario woud be selling 3 km of fiber at $1000 per meter for a total of $3,000,000.

Cost Estimation

According to “Market Analysis of a Privately Owned and Operated Space Station” from 2017 by US Science and Technology Policy Institute, ZBLAN sells for $175 to $1000 per meter, depending on the quality of the fiber (ThorLabs, FiberLabs) .1

Another study set commercial market price for ZBLAN fibers at $150/meter to $300/meter and best quality exotic fibers from $300/meter to $3,000/meter. 4

Market Size Estimation

Fiber optic market

According to Grand View Research, the fibre optics industry had gross global sales of €4.7 billion in 2015. 5

Another study estimated the fibre optic market will expand at a CAGR of 10% during 2017-2023 and is anticipated to reach the valuation of €5.2 billion by the 2023. 6

According to IBISWorld, the revenue for the optical fibre and cable manufacturing industry is expected to increase 16.0% to $53.75 billion in 2018 and has been growing at an average annualized rate of 19.2%.7

ZBLAN market

According to “Market Analysis of a Privately Owned and Operated Space Station” published in 2017, the sales of ZBLAN form a very small part of the $3 billion market, but analyst estimated that ZBLAN might be able to capture sales of €260 million to €350 million annually, which would be 10 to 13 percent of the current market. They authors estimated that iff ZBLAN increases its market share by 1 percentage point per year over the next decade, by 2028 its share is likely to be in that range.1

Figure on slide 18 released by NASA Emerging Space Office in 2014 illustrates the potential market share for ZBLAN applications and sets the total at $20 billion.2

In 2006, ZBLAN fibre market was estimated to be $7.56 billion per year. NASA published news based on Kessler Market Intelligence: Spectroscopy $15 Million, Laser Surgery $25 Million, Imaging Fiber Bundle $15 Million, Telecommunications $7500 Million.8

In 1998, NASA estimated that the commercial potential for ZBLAN to be $2.5 billion a year in the communications industry.9

Earthly Solution Risk

Very high. Research published in 2018 by Teng-Cheong Ong et al. found that crystallization is suppressed when ZBLAN is cooled very rapidly.

NASA is licensing similar technology: " Combination of a vertical magnetic field and a rapid cool down from the crystallite melting temperature will ensure that no crystals are present in the preform after processing."

Risks

- Market size (niche market)

- Number of customers

- Preform cost

- Transmission loss versus cost

- Patents